Jukang production molds are in full compliance with ISO9001 standards. The company introduces advanced measuring equipment and quality management systems to control every aspect from design to production and acceptance. The ultimate satisfaction of the customer is the consistent requirement of Ju Kang for quality.

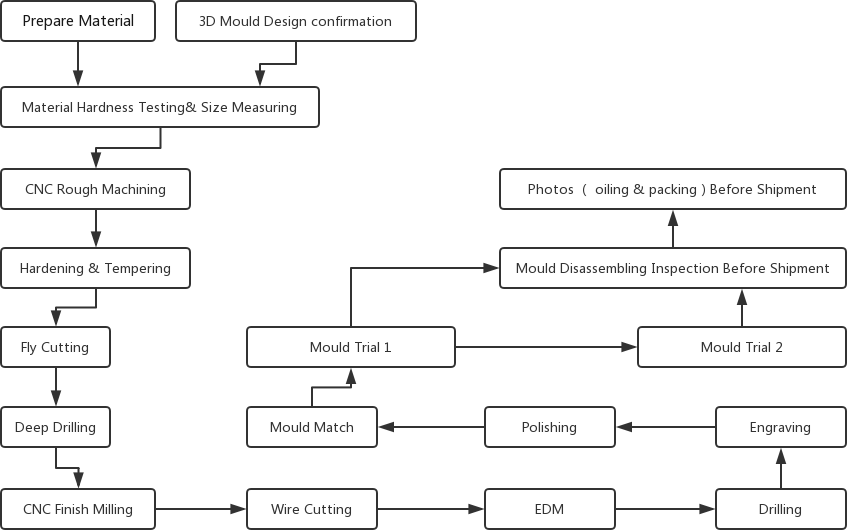

After the mold design is completed, we retain the CAD data, then the mold production, using CMM testing equipment, electronic measuring instrument for testing. All procedures are carried out by our experienced staff in strict accordance with quality control standards to ensure that the products can meet the specific requirements of customers.

Mould Steel Hardness,Dimension Inspection

Mould Electrodes Inspection

Mould Parts Dimension Inspection

Mould Parts Dimension Inspection

Mould Trial Report and Samples Inspection

Mould Shipment Final Inspection

The company can provide product analysis and mold flow analysis reports, and provide customers with timely feedback on problems found on the drawings, such as thin areas, sink marks, weld marks, pores, undercuts, gate locations, gate types, etc.

Steel suppliers are required to provide steel quality assurance certificates and material certificates, and Ju Kang Mold will conduct steel inspection before acceptance.

Quality control and project management progress for key processes will be documented and customer progress and quality reports will be provided weekly. The mold technician must carefully check the appearance of the mold and the assembly process of the mold in accordance with company standards.

We will focus on qualified spare parts to meet our customers' requirements for standard part models, quality standards and procurement time.

Material handling will be carried out according to the established process, and relative inspection will be carried out to strictly check the core, cavity, insert, guide post, return pin, angle lift, slider, thimble, cooling system and connector.

Prepare documents before shipment, such as spare parts list, mold inspection video, process documents, 2D/3D drawings, etc. We will pack and transport according to customer's requirements to ensure the safety of shipping and air transportation.

Add: No. 2 Gongxin Avenue, North City Development Zone, Huangyan, Taizhou, Zhejiang

Tel: 0576-84399777

Fax: 0576-84287096

Email: cccmould@163.com tzjkmould@163.com